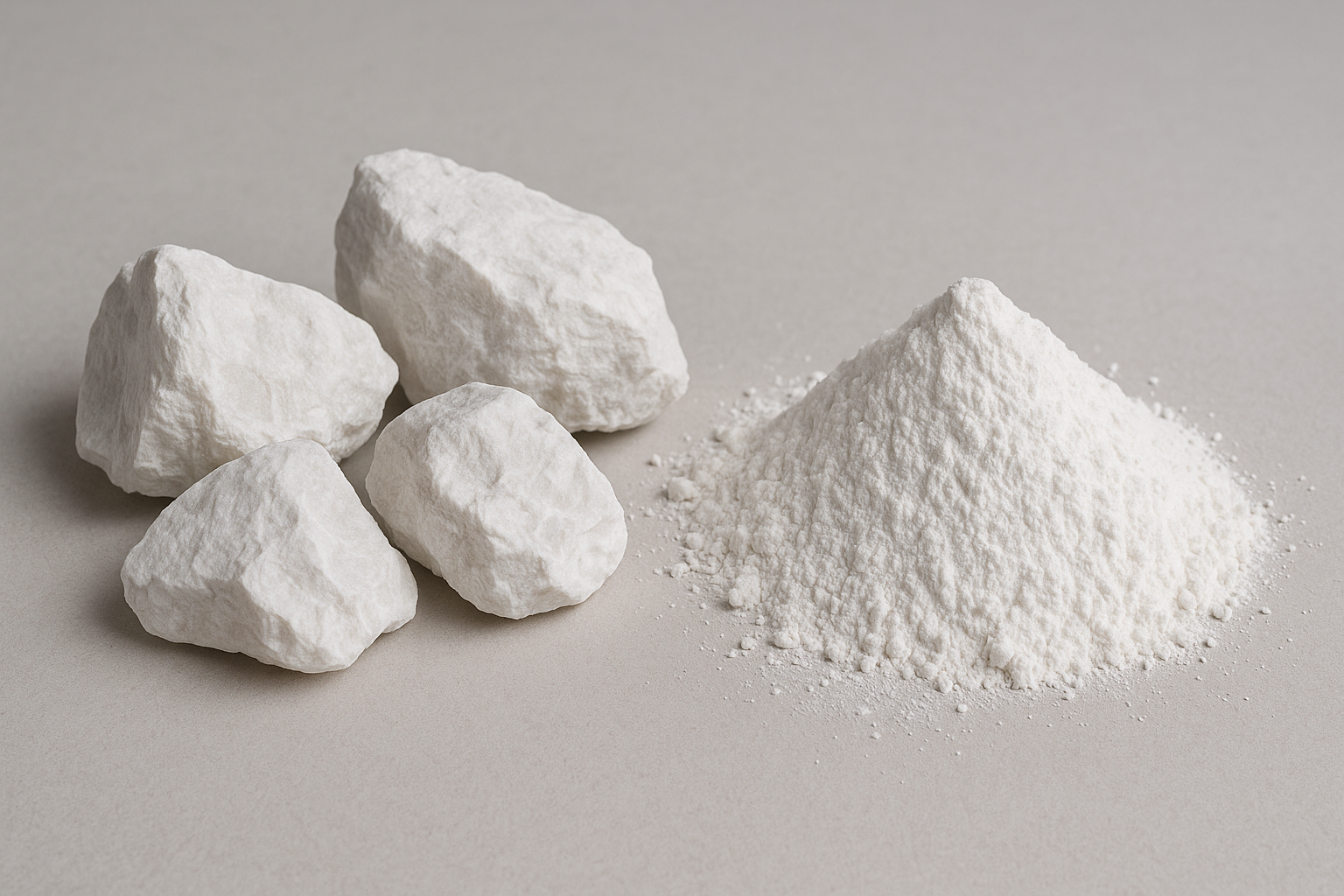

Talc

Talc is scientifically known as hydrated magnesium silicate, a soft mineral with a unique composition that makes it an essential component in many industries. Thanks to its physical and chemical properties, talc is used as a filler to improve hardness, flexibility, and durability in products such as plastics, rubber, and paints. It is also used in paper manufacturing to improve smoothness and gloss, and in cosmetics to enhance texture and product stability.

Properties and characteristics of talc:

The properties of talc vary according to its purity and impurity content. It can appear in the following colours:

- White

- Off-white

- Transparent

- Light green (rare)

How is it extracted?

The process of extracting talc begins in surface mines, especially in areas where the rock cover is thin. Subsurface mines may be used in cases where the ore is found at great depths. After extraction, the ore is sorted manually or by photoelectric separation according to its fineness and visual characteristics, then crushed, ground and treated to remove impurities, especially iron. The process is completed using various grinding and screening techniques according to the specifications required by the local or international market, including jet milling, water milling and vertical milling.

Uses of talc

Features of agricultural talc:

- Used in the fertilizer industry as an anti-caking agent, preventing ingredients from sticking together and forming clumps during storage or distribution.

- Has a layered (flaky) structure, which facilitates dispersion within fertilizer ingredients and enhances its effectiveness.

- It acts as a natural lubricant thanks to its low shear strength, which improves the flow of materials during industrial processing.

- It is used as an effective carrier in the animal feed, agricultural pesticide, and insecticide industries.

Specifications and uses:

- Talc is extracted from nature in the form of a multi-layered mineral, with colours ranging from:

-White

-Pink

-Light green

- Grey

- When ground, it turns into a fine white or grey powder.

- Chemical formula: Mg₃Si₄O₁₀(OH)₂ (hydrated magnesium silicate)

- True specific gravity: 2.7

- Hardness: 1 on the Mohs scale (the softest of inorganic minerals)

- Excellent thermal and chemical resistance

Product applications:

- Fertiliser industry

- Animal feed

- Seed coating

- Fruit protection

- Carrier in agricultural pesticides

- Aid in olive oil production (to increase yield and improve quality)

- Anti-adhesive agent in foods such as chewing gum, sweets, and rice polishing

Product Features:

- Granules made from 100% mica powder using wet grinding technology, without any carriers or resins.

- Addresses the high viscosity issue of wet mica powder, making it more suitable for industrial applications.

- Environmentally friendly, dust-free, easy to clean and collect, and contributes to improved operating efficiency.

Technical Specifications:

- Mica mesh: 1250 mesh

- Granule length: 3 to 6 mm

- Available for manufacture according to customer-specific specifications.

Areas of use:

Suitable for cooling and air conditioning components and units, such as:

- Refrigerators

- Washing machines

- Air conditioners

Product features:

- Made from 100% pure talc powder, without any carriers or resins.

- Environmentally friendly, dust emission-free, easy to clean and use.

- Facilitates production processes and improves operational efficiency in various manufacturing environments.

Technical Specifications:

- Fineness: 800 to 3000 mesh (as per request)

- Diameter: 2.5 mm

- Agriculture

- Food industry

- Plastics industry

- Chemical industry

Uses:

Suitable for a wide range of industries that rely on talc powder, including:

Product features:

- Transparent masterbatch is characterised by high transparency, making it ideal for transparent product applications.

- It provides a cleaner production environment thanks to its dust-free properties, improving working conditions and facilitating processing operations.

- The PE masterbatch is a cost-effective solution for manufacturers.

- An economical solution that helps companies reduce costs without compromising on final quality.

Specifications and uses:

- Macron is manufactured from high-purity transparent talc powder, with polyethylene (PE) as a carrier.

- It has the following characteristics:

- Clear gloss

- Uniform distribution

- Excellent durability

- Low density

- High transparency

- High tensile strength

- The refractive index of the product ranges between 1.5 and 1.6, which is consistent with the refractive index of PE (1.43 – 1.63), enhancing the clarity of the final product.

Product applications:

- Transparent films

- Transparent plastic barrels

- Transparent fast food containers

Features of biodegradable talc powder:

- Excellent dispersion and improved flow: Facilitates processing in various production lines and increases operational efficiency.

- High loading capacity: Contains high-quality grades of talc, allowing for a higher filler ratio compared to traditional filler batches.

- Safe and non-toxic: Causes no pollution and is environmentally friendly.

- Biodegradable: Degrades under composting conditions, making it a sustainable choice for environmentally friendly products.

- Economical solution: Helps reduce operating costs without affecting the performance of the final product.

Specifications and uses:

- Environmental composition: Made from a mixture of starch (tapioca or corn) with bio-based resins such as:

- PLA (polylactic acid)

- PBS (polybutylene succinate)

- PBAT (polybutylene adipate terephthalate)

- TPS (thermally processed starch)

- Ideal carrier for biodegradable materials: Used as an effective carrier for the production of bioplastics and their applications.

Product applications:

- Biodegradable shopping bags

- Blown film extrusion

- Injection moulding

Features of polypropylene (PP) talc powder:

- Ultra-fine particles: Contains high-quality talc with a fine particle size, which improves the mechanical and thermal properties of PP.

- Reduced dust emission: Contributes to a better working environment and increases operational efficiency through easy cleaning and handling.

- Advanced processing performance: Provides easy distribution within the material thanks to the layered structure of talc, which improves dimensional stability and final performance.

- Economical solution: It is a cost-effective option without compromising the quality of the final product.

- Higher performance than raw talc: Masterbatch containing PP as a carrier provides uniform, dust-free distribution with improved mechanical properties.

Technical specifications:

- Talc mesh: 800 to 3000 mesh (upon request)

- Carrier ratio: 20% to 30%

- We can customise the product according to the customer's quality requirements and technical specifications.

Product applications:

- Modified PP products

- Blown film, injection moulding and blow moulding

- Extrusion sheet

- Automotive and electrical industries

- Film, bottles, sheets and pipes

Advantages of talc powder for paper manufacturing:

- Reduced wear: Reduces wear on fabrics and machine parts during paper production processes.

- Uniform distribution: Thanks to its layered structure, talc is distributed evenly across the surface, reducing defects such as spots and holes.

- Improved printing: Improves printability and enhances image quality on the finished paper.

- Increased opacity and whiteness: Contributes to increased paper opacity and whiteness, enhancing its commercial value.

Specifications and uses:

- Talc is a natural mineral composed of magnesium, silicon, oxygen, and hydrogen.

- Chemical formula: Mg₃Si₄O₁₀(OH)₂

- In the paper industry, talc is used as a raw material and an auxiliary agent in the manufacturing stages, where it improves paper absorption and enhances drying properties, especially in papers intended for printing.

Product applications:

- RCF paper manufacturing

- Newspapers and paper towels

- Printing and writing paper

- Specialty papers and packaging

Benefits of talcum powder for personal care and makeup:

- Gentle abrasive: Helps clean teeth and improve their shine by gently removing deposits.

- Effective absorbent: Absorbs moisture and oils, keeping skin dry and comfortable.

- Anti-caking: Prevents solid particles in cosmetic powders from clumping, ensuring smooth and even distribution.

- Improved texture: Reduces stickiness in creams and balms, giving the skin a smooth texture.

- Enhances visual density: Reduces the transparency of cosmetics and provides natural coverage.

- Protects the skin: Forms a light barrier against harmful external factors.

Specifications and uses:

- Talc is a soft natural mineral extracted from the earth, consisting of:

- Magnesium, silicon, oxygen, and hydrogen.

- Chemical formula: Mg₃Si₄O₁₀(OH)₂.

- It is widely used in personal care thanks to its high ability to absorb moisture, soften the skin's surface, and reduce shine in cosmetics.

Main applications:

- Baby powder

- Face and body powder

- Blush

- Eye shadow

- Foundation

Features of talc powder for cables:

- Talc powder for cables is characterised by its extreme fineness, high purity and excellent insulating properties, with effective resistance to ultraviolet rays, making it suitable for use in insulating wires and cables.

- It enhances the tensile strength and tear resistance of rubber products and contributes to improved dimensional stability and environmental resistance.

- It provides high thermal stability, resistance to leaching and degradation, and good dispersion, with ease of addition in small quantities.

- It is widely used in rubber products such as tyres, hoses, gloves, rubber threads, and cables.

Specifications and uses:

- Talc used in cables has enhanced tensile strength, water resistance, and corrosion resistance, which reduces the impact of environmental factors and slows down the ageing process.

- It is characterised by its white colour, affordable price, and easy dispersion, which contributes to reducing production costs without affecting the quality or colour of products, even in coloured rubber.

- It is ideal for use in recycled rubber products, as it improves the final performance while keeping costs within the target range.

Product applications:

- Mining cables

- Pipeline cables

- Communication cables

- Marine cables

- Outdoor cables

- Engineering cables and special applications

Advantages of talc powder for shoes and EVA materials:

- It has a skeletal structure that helps enhance adhesion with materials and improve their flow during processing.

- It enhances tensile strength and tear resistance, and contributes to the dimensional stability of the product, thereby improving its quality and durability.

- Talc powder for synthetic rubber is characterised by high thermal stability, excellent dispersion, resistance to bleeding and decomposition, as well as UV resistance, which increases its service life.

- It can be added in small quantities without affecting the properties of the base material, while significantly improving overall performance.

Specifications and uses:

- Talc powder for elastomers (synthetic rubber) provides structural support, improves flexibility, abrasion resistance and stability, and prevents chipping and cracking in intensive use.

- Talc powder for EVA foam is characterised by excellent compatibility with several types of thermoplastics such as:

- EVA, TPR, TPV, TPE, EPDM

- making it ideal for applications requiring high flexibility and anti-slip properties such as footwear, rubber and cables.

Product applications:

- Sports and casual footwear

- Shoe insoles for global brands

Advantages of talc powder for rubber:

- Talc powder has excellent compatibility and mixability with rubber compounds, which improves fluidity and ease of processing during manufacturing.

- It contributes to enhancing tensile strength and tear resistance, and helps maintain the dimensional stability of the final product.

- It has high thermal stability, resistance to bleeding and thermal decomposition, as well as homogeneous dispersion and easy addition even in small quantities.

- It provides UV protection, which extends the life of the product.

- It helps the additive compound spread evenly during storage, improving its distribution within the material.

Technical specifications and benefits:

- It reduces the cost of rubber compounds without affecting performance.

- It improves processing technology and gives the final product better mechanical properties.

- Suitable for coloured rubber without affecting colour tones.

- Has positive properties that make it ideal for use in recycled rubber products.

Product applications:

Macron talc powder is used in a wide range of rubber products such as:

- Tyres

- Hoses

- Rubber threads

- Gloves

- Cables

Advantages of performance improvement in the Lithotronic system:

- Effective moisture absorption without washing or bleeding in the fountain solution.

- Maintains colour stability and strength during printing.

- Provides high efficiency in dye distribution, which improves ink productivity and extends its life on paper.

- Reduces ink penetration into paper fibres, improving the quality of the final print.

- Enhances print resistance to fading and smudging, and reduces strike-through.

- It can be used in high addition ratios, which helps reduce production costs without affecting quality.

Specifications and uses:

- Talc is extracted from nature with a multi-layered structure and is available in white, pink, grey and light green colours.

- After grinding, it produces a fine white or grey powder.

- Chemical name: Hydrated magnesium silicate

- Formula: Mg₃Si₄O₁₀(OH)₂

- Specific gravity: 2.7

- Hardness: 1 on the Mohs scale (the softest of all minerals)

- China is the world's largest producer and exporter of high-purity talc, which is used in advanced industrial applications.

- Talc, with its flaky particles, acts as a ‘bridge’ within the paint, improving cohesion and reducing clay cracking.

- The higher the length-to-width ratio of the particles, the greater the crack resistance and the better the mechanical properties.

- In oil-based paints:

- Coarse, flaky talc imparts a glossy, silky effect.

- Fine talc absorbs excess binder and provides a perfectly flat surface for paints below the critical PVC level.

Product applications:

- Building paints and interior finishes

- General industrial paints

- Automotive paints

- Wood and furniture paints

- Ink manufacturing

Product features:

- The talc used in construction coatings enhances the cohesion of the coating layer and improves its quality, which helps reduce costs for manufacturers.

- It reduces the amount of base pigments required, making the production process more economically efficient.

- It helps control gloss and improves the distribution of other pigments within the paint formulation.

- It contributes to increased paint durability and enhances its stability in emulsion paints, extending the product's life and maintaining its quality over time.

Product features:

- High-quality talc enhances the crack resistance of clay in coating layers, extending product life and reducing costs for manufacturers.

- It features effective moisture absorption, pure whiteness, uniform particle distribution, and excellent dispersion, which prevents sedimentation and improves the coating's resistance to ageing and weathering.

- It improves rust and corrosion protection properties, making it ideal for use in harsh environments.

- The precise particle spectrum helps to enhance the bond between the pigment and the binder, reducing unwanted redness while maintaining the gloss of the paint.

- Gives the paint a silky texture and a refined glossy appearance that reflects the quality of the manufacturing.

Technical specifications and uses:

- Talc is extracted from nature with a multi-layered structure and is available in white, pink, grey and light green colours.

- After grinding, it turns into a fine white or grey powder.

- Chemical name: Hydrated magnesium silicate

- Chemical formula: Mg₃Si₄O₁₀(OH)₂

- Specific gravity: 2.7

- Hardness: 1 on the Mohs scale (the softest known mineral)

- China is the world's largest producer and exporter of high-purity talc used in industrial applications.

- With its flaky particles, talc acts as a ‘bridge’ within the coating, improving cohesion and reducing clay cracking.

- The higher the length-to-width ratio of the particles, the greater the crack resistance and the better the mechanical properties.

In oil-based paints:

- Coarse, flaky particles impart a glossy, silky effect.

- Fine particles absorb excess binder and give a flat effect ideal for paints below the critical PVC level.

Product applications:

- Building paints and interior finishes

- General industrial paints

- Automotive paints

- Wood and furniture paints

- Ink manufacturing

Product features:

- The talc powder used in paints enhances the coating's resistance to cracking (clay cracking), improving durability and reducing production costs.

- It gives indoor paints a smooth, silky appearance, enhancing the appeal of the final coating.

- In anti-corrosive paints, talc improves rust and corrosion protection properties.

- It is used in emulsified interior wall paints to enhance stability and prevent separation or sedimentation.

Specifications and uses:

- Talc is extracted from nature with a multi-layered structure and is available in white, pink, grey and light green colours.

- After grinding, it produces a fine white or grey powder.

- Chemical name: Hydrated magnesium silicate

- Formula: Mg₃Si₄O₁₀(OH)₂

- Specific gravity: 2.7

- Hardness: 1 on the Mohs scale (the softest mineral)

- China is the world's largest producer and exporter of high-purity talc, which is used in advanced industrial applications.

- With its flaky particles, talc acts as a ‘bridge’ within the paint, improving cohesion and reducing clay cracking.

- The higher the length-to-width ratio of the particles, the greater the crack resistance and the better the mechanical properties.

- In oil-based paints, coarse, flaky talc particles add a glossy, silky effect.

- Fine talc, on the other hand, absorbs excess binder and gives a flat effect ideal for paints below the critical PVC level.

Product applications:

- Building paints and interior finishes

- General industrial paints

- Automotive paints

- Wood and furniture paints

- Ink manufacturing

Features, specifications and uses of talc powder for marine paints:

- Enhances the coating's resistance to cracking and improves overall performance, while reducing costs for manufacturers.

- Has strong moisture absorption properties, which prevents the precipitation of coating components.

- Gives the paint high whiteness, uniform particle size, and excellent dispersion.

- Provides effective coverage on surfaces, enhancing the efficiency of the paint.

- It reduces paint ageing and improves its resistance to various weather conditions.

- It is effectively used in anti-corrosion paints to enhance protection against rust and corrosion, especially in marine coatings.

- The proportion of talc in anti-corrosion paint ranges from 10% to 30%.

- Tackle fineness: 20 to 100 microns.

- Oil absorption: between 20 and 60 g per 100 g of tackle.

- Physical and chemical properties:

- Chemical formula: Mg₃Si₄O₁₀(OH)₂

- Specific gravity: 2.7

- Hardness (Mohs): 1 (one of the softest inorganic minerals)

- It has excellent thermal and chemical stability.

- Its flaky particles act as a bridge between the components of the coating, enhancing cohesion and crack resistance.

- In anti-rust paints, it provides a strong barrier against corrosion and performs well in salt spray tests.

- It is easily incorporated into various paint formulations.

Applications of talc powder:

- Building paints and interior and exterior finishes

- General industrial paints

- Automotive paints

- Wood and furniture coatings

- Ink manufacturing

Product features, specifications and uses:

- Talc powder for blow moulding processes is characterised by high DOP content, which allows for optimal distribution within plastic raw materials.

- Accurate colour stability according to the Gardner scale and easy matching of final colours.

- Contributes to reducing the shrinkage rate during moulding, which improves the smoothness and quality of the product's outer surface.

- Enhances surface hardness and scratch resistance, especially in polyethylene and polypropylene.

- Gives plastic products higher durability and greater resistance to use.

Increases tensile strength within a certain range, with a balance of mechanical properties such as:

- Impact resistance

- Heat resistance

- Hardness

- Ageing resistance

Provides increased strength or reduced weight depending on production requirements.

Achieves greater stability in the final dimensions of the product.

Has effective flame retardant properties.

Reduces wear and tear on production lines and equipment thanks to its superior smoothness.

Provides a bright white colour for a clean and professional appearance.

Product applications:

Talc powder for blow moulding is used in a wide range of plastics, including:

- PE (polyethylene)

- PP (polypropylene)

- PVC (polyvinyl chloride)

- PA (polyamide)

- PC (polycarbonate)

- ABS (acrylonitrile butadiene styrene)

- TPU (thermoplastic polyurethane)

- PS (polystyrene)

- EVA (ethylene vinyl acetate)

- PETG (polyethylene terephthalate glycol)

Product features, specifications and uses:

- The talc used in plastic foam is characterised by high DOP, colour stability (Gardner) and ease of colour matching.

- It helps to reduce the moulding shrinkage rate of plastic products, resulting in improved surface properties.

- It enhances surface hardness and scratch resistance when added to materials such as polyethylene and polypropylene.

- It increases tensile strength in a specific range when used in modified plastics.

- It gives plastics uniform strength, greater impact resistance, heat resistance, hardness, and anti aging.

- Provides greater strength or lightness, with higher dimensional stability and good flame retardancy.

- It's high smoothness reduces machine wear during processing.

- It has a high degree of whiteness that helps achieve maximum product brightness.

Plastics processed with it can be used as a substitute for metal structures in many industries and applications such as:

- Injection moulding

- Blow moulding

- Extrusion sheets

- Foam

This type of talc powder is processed using high-quality raw materials to meet the growing demand in the market.

It is used as an additive or filler in a wide range of industries, including:

- Plastics

- Paint

- Ceramics

- Cosmetics

- Rubber

- Paper industry

- Agriculture

- Food

- Pharmaceuticals

It is characterized by a soft texture, low abrasion, high gloss, low oil absorption, and good transparency.

Product applications:

- Polyethylene foam (PE foam)

- Polystyrene foam (PS foam)

- Ethylene vinyl acetate foam (EVA foam)

- Thermoplastic elastomer foam (TPE foam)

- Thermoplastic polyurethane foam (TPU foam)

Product features, specifications and uses:

- Talc powder for general plastics comes in the form of a very fine micron powder, with high dispersion, colour stability (Gardner) and ease of colour matching.

- The talc powder content used in moulding significantly increases the flexural modulus, i.e. the hardness of the product.

- Adding talc powder to PP compounds and nylon compounds during extrusion moulding enhances the melt strength of the plastic.

- It improves product properties such as fluidity, mould shrinkage, and hardness.

- It makes mechanical properties such as strength, impact resistance, heat resistance, hardness, and ageing resistance more uniform.

- It is produced with high precision using high-quality talc, with a very fine particle size, and features superior gloss and a stable appearance.

- The high silicon dioxide content enhances the flexural modulus, impact strength, and tensile strength.

- High purity improves dimensional stability in the final products.

- Enhances the performance of engineering plastics when modifying plastics, providing lighter weight or higher strength.

- Provides greater dimensional stability and good flame retardant.

- Reduces machine wear during manufacturing due to its superior smoothness.

- High whiteness helps achieve maximum brightness in the final product.

Product applications:

- Polyoxymethylene (polyformaldehyde)

- Polycarbonate

- Glycol-modified PET – Polyester

- Modified polyphenylene oxide

- Polyethylene terephthalate

- Resistant engineering plastics

- Conductive engineering plastics

- Radiation-modified engineering plastics

- Primary colouring agents for engineering plastics

Product features, specifications and uses

- Talc powder for engineering plastics helps improve the moulding shrinkage rate of plastic products, resulting in improved final surface quality.

- It enhances surface hardness and scratch resistance when added to polyethylene and polypropylene.

- It can increase the tensile strength of modified plastics within a specific range.

- It makes mechanical properties such as strength, impact resistance, heat resistance, hardness, and ageing resistance more uniform.

- It is produced precisely according to physical and chemical properties, using high-quality talc with extremely fine particle size.

- It features high DOP content, colour stability (Gardner), and easy colour matching.

- The high silicon dioxide content enhances tensile strength and impact resistance.

- High purity improves product dimensional stability.

- Enhances the performance of engineering plastics when modifying plastics and provides higher strength or weight reduction.

- Provides greater dimensional stability and effective flame retardancy.

- Its smoothness reduces machine wear during manufacturing, and its high whiteness achieves maximum brightness.

- Used as a substitute for metal structures in industrial applications through processes such as injection moulding, blow moulding, extrusion, and foaming.

Product Applications

- Polyoxymethylene (polyformaldehyde)

- Polycarbonate

- Glycol-modified PET – Polyester

- Modified polyphenylene oxide

- Polyethylene terephthalate

- Resistant engineering plastics

- Conductive engineering plastics

- Radiation-modified engineering plastics

- Primary colouring agents for engineering plastics

Product features, specifications and uses

- The use of talc in recycled plastic compounds helps restore mechanical performance and improve dimensional stability.

- In recycled polypropylene (rPP) compounds, the finer the talc particle size, the greater the positive effect on the flexural modulus, enhancing stiffness and heat resistance.

- Talc-reinforced recycled plastic covers provide a significant improvement in the heat resistance of PP compounds.

- Al-Aseel produces different grades of talc powder with precision, controlling particle size distribution and colour characteristics to suit the requirements of the recycling industry.

- Talc provides higher mechanical strength, weight reduction, better dimensional stability, and effective flame retardancy.

- The exceptional smoothness of talc powder reduces machine wear during manufacturing processes.

- It features a high degree of whiteness to achieve optimal brightness in the final product.

Product Applications

- Recycled polypropylene (rPP)

- Recycled polyethylene (rPE)

- Polyvinyl chloride (PVC)

Product Features

- The product is based on talc-reinforced PLA composite material, which provides excellent heat resistance, high rigidity, and an attractive finish.

- The product features a short manufacturing cycle, light weight, and low cost, making it ideal for high-efficiency industrial applications.

- Talc improves the tensile strength and impact resistance of PLA films while maintaining acceptable elongation properties.

- The composite materials exhibit excellent mechanical properties, with tensile strength ranging from 50 to 70 MPa, thanks to the incorporation of natural talc powder with soluble acid.

- Talc is used as a catalyst to accelerate and enhance crystallisation in PLA, significantly improving its thermal resistance.

- The resulting materials are fully biodegradable, environmentally friendly and suitable for multiple green applications.

- This product is manufactured by Al-Aseel Biodegradable Plastics and aims to reduce costs while providing effective solutions for the preparation of high-quality, high-performance heat-resistant PLA compounds.

- It is suitable for various industries that require lightweight, mechanically strong, and environmentally friendly materials.

Product applications

- Polybutylene succinate (PBS)

- Polyadipate/butylene terephthalate (PBAT)

- Poly glycolic acid (PGA)

- Polycaprolactone (PCL)

Product Features

- Talc enhances the performance of polyolefin compounds in automotive applications, opening up a wide range of possibilities for use in various components.

- It is available in multiple grades for multiple parts within vehicles, with precise control over particle size distribution, ensuring accuracy in assembly and reproducibility.

- The talc content in modified plastics increases the flexural modulus (stiffness), achieving stronger mechanical performance.

- Talc is used as a substitute or supplement for glass fibers in automotive polyamides, improving the cost-performance ratio and enhancing dimensional stability and surface quality.

- Talc improves the balance of stiffness and impact resistance, and increases HDT (heat deflection temperature) and dimensional stability, especially in lightweight plastic parts.

- Using high-purity materials and precise control of fineness, ultra-fine talc powder is produced with excellent dispersion properties, colour stability (Gardner) and ease of colour matching.

- The high silicon dioxide content enhances tensile strength and impact strength, while the high purity contributes to dimensional stability and product longevity.

- Talc contributes to weight reduction, reduced thermal expansion and contraction, improved flame resistance, and reduced machine wear due to its high smoothness.

- It features exceptional whiteness for optimal brightness and a smooth texture suitable for precision applications.

- It is used as a filler or modifier to improve the mechanical and optical properties of plastic automotive parts, especially as car companies are moving towards using plastic instead of metal to reduce cost and weight.

Product Applications

- Under-the-bonnet parts

- Dashboard and interior trim

- Shock absorbers

- Body panels

- Exterior trim

Talc is used as a nucleating agent in zero gap design applications to reduce expansion and contraction.

Improves the performance of recycled automotive plastics in terms of stiffness, heat resistance, and dimensional stability.

Ideal for lightweight foam applications in vehicles.

Product Features

- The talc powder used in extrusion sheets has high DOP properties, with stable colour according to the Gardner scale and easy colour matching.

- Adding talc powder from Al-Aseel to the plastic used in extrusion sheets improves the moulding shrinkage rate of products, resulting in improved texture and surface quality.

- When added to polyethylene and polypropylene, talc enhances surface hardness and scratch resistance.

- Talc contributes to increasing the tensile strength of plastic products within a specific range and improves the balance of properties such as impact resistance, heat resistance, hardness, and ageing resistance.

- Talc powder from Al-Aseel is characterised by a high degree of whiteness, which gives products perfect brightness and reduces machine wear thanks to its exceptional smoothness during processing.

- It provides greater dimensional stability and contributes to weight reduction while improving flame resistance.

- The talc used has a soft texture, low abrasion, high gloss, low oil absorption and excellent transparency, making it ideal as an additive or filler in many industries.

Product applications

- Polyoxymethylene (polyformaldehyde)

- Polycarbonate

- Glycol-modified PET (polyester)

- Modified polyphenylene oxide

- Polyethylene terephthalate

- Resistant engineering plastics

- Modified conductive engineering plastics

- Radiation-modified plastics

Primary uses in the modification and dyeing of engineering plastics

Product Features

- Talc powder for electrical applications ranges from micron powder to ultra-fine powder, and is characterised by high dispersion, colour stability (according to the Gardner scale), and easy colour matching.

- Adding talc powder to electrical plastics significantly increases the flexural modulus, which means improved product rigidity.

- Using our talc powder with polypropylene and nylon in extrusion moulding processes effectively helps improve the melt strength of plastics.

- The talc content in modified plastics enhances the properties of plastics, such as fluidity, mould shrinkage, and rigidity.

- Talc powder used in engineering plastics makes properties such as impact resistance, heat resistance, rigidity, and ageing resistance more balanced and uniform.

Product specifications and uses

- We rely on high-quality talc in our production, with precise control of particle size, to produce a very fine powder with properties such as high dispersion, colour stability, and easy colour matching.

- The high silicon dioxide content enhances the tensile strength and impact of the products, while the high purity of the talc improves dimensional stability.

- These properties enhance the efficiency of engineering plastics when used in plastic modification.

Talc powder is used as an additive, modifier, or filler in many electrical industry components, such as:

- Body covers and device shells

- Electrical components

- Refrigerator drawers

- Roller washers

- Other plastic injection parts

Product Applications

- Polyoxymethylene (polyformaldehyde)

- Polycarbonate

- Glycol-modified PET (polyester)

- Modified polyphenylene oxide

- Polyethylene terephthalate

- Engineering plastics resistance

- Modified conductive engineering plastics

- Radiation-modified engineering plastics

Product Features

- Talc powder has high purity and low iron oxide content.

- Superior talc powder for ceramics gives ceramics a beautiful white colour after firing.

- Talc powder for tableware improves the thermal shock resistance of ceramics and reduces breakage.

- Talc for ceramic glazing makes ceramics resistant to acids.

Product specifications and uses

- Talc powder is used in many applications in the ceramics sector, such as technical ceramics, automotive ceramics, tiles, and fire-resistant ceramics.

- The fine crystalline structure of our talc powder makes it suitable for use in electrical ceramic applications.

- Talc powder is an auxiliary agent in the ceramics industry and is characterised by its resistance to high temperatures.

- The addition of talc improves the mechanical and optical properties of ceramics and glass coatings and helps to reduce the combustion temperature, thereby reducing production costs.

- Talc is a key component in catalytic converters and petrol/diesel particulate filters, and can improve electrical resistance when mixed with kaolin.

Talc in the electronics industry

- Talc is a poor conductor of electricity and is therefore used in the manufacture of ceramic goods for the electrical industry.

- The iron oxide content must not exceed 1% so as not to increase the electrical insulation constant or cause an unattractive colour in the product.

Product applications

- Tiles

- Sanitary ware

- Tableware and artwork

- Industrial ceramics

Product Features

- Talc powder has high purity and low iron oxide content.

- Superior talc powder for ceramics gives ceramics a beautiful white colour after firing.

- Talc powder for tableware improves the thermal shock resistance of ceramics and reduces breakage.

- Talc for ceramic glazing makes ceramics resistant to acids.

Product specifications and uses

- Talc powder is used in many applications in the ceramics sector, such as: as a filler in technical ceramics, automotive ceramics, many types of tiles, and fire-resistant ceramics. The fine crystalline structure of our talc powder also allows it to be used in electrical ceramic applications.

- Talc powder is an auxiliary agent in the ceramic industry and is characterised by its resistance to high temperatures. Overall, the addition of talc enhances the mechanical and optical properties of ceramics and glass coatings. It also allows for the modification of product properties and reduction of combustion temperature, contributing to lower production costs.

- Talc is the main component of catalytic converters and petrol/diesel particulate filters, and can improve electrical resistance when mixed with kaolin.

Talc in the electronics industry

- Talc is a poor conductor of electricity, which is why it is used in the manufacture of ceramic goods for the electrical industry.

- The iron oxide content must not exceed 1%, as an increase in this content may lead to a rise in the electrical insulation constant of the product, in addition to giving it an unattractive colour.

Product applications

- Tiles

- Sanitary ware

- Tableware and artwork

- Industrial ceramics

Product Features

- Talc powder in tiles improves the thermal shock resistance of ceramics and reduces breakage.

- Talc powder for tiles gives ceramics a white appearance.

- Talc for porcelain tiles makes ceramics resistant to acids.

- Talc powder in tiles naturally helps prevent water leakage in sanitary ware.

Product Specifications and Usage

- The talc powder grinding process is highly customisable. Therefore, it is possible to achieve the desired particle size that suits each type of ceramic product instead of a one-size-fits-all approach.

- Talc powder for tiles is a good catalyst in the ceramic industry and has high temperature resistance.

In general, the addition of talc powder has positive effects on ceramics, for example, it increases the mechanical and optical properties of ceramic materials and glass coatings. By adding talc, the properties of the ceramic product can be changed and the firing temperature reduced. This has a positive effect on production costs.

Product applications

- Tiles

- Sanitary ware

- Tableware and artworks

- Industrial ceramics

Product Features

- White talc powder for ceramics gives ceramics a beautiful white colour after firing.

- Talc powder for tableware improves the thermal shock resistance of ceramics and reduces breakage.

- Talc for ceramic glazing makes ceramics resistant to acids.

- Talc powder for food containers prevents water leakage.

Product Specifications and Uses

- The talc powder grinding process is highly modifiable, allowing the desired particle size to be achieved for each type of ceramic product instead of a one-size-fits-all approach.

- For tableware ceramics, sanitary ware, traditional ceramics, technical ceramics, and tiles, we offer a complete range of talc powder to improve glazing, reduce firing temperatures, and achieve a range of other benefits.

- Natural mineral talc is an essential material for all types of ceramics, as it improves the glazing process, allowing for reduced firing temperatures and shorter firing cycles.

Product Applications

- Tiles

- Sanitary ware

- Tableware and artworks

- Industrial ceramics